Automated Particle Counter - Density and Conductivity

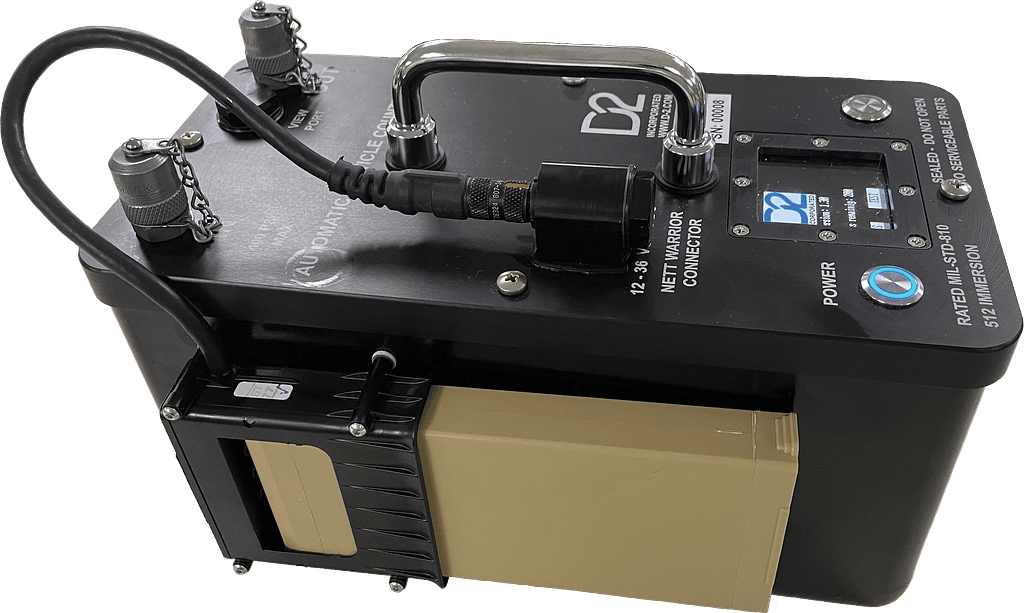

This is the portable military hardened submersible / waterproof automated particle counter that also has conductivity and density measurement built in. This Particle Counter is found in the PEAK Kit.

The Particle counter provides equivalent testing for: ASTM D7619 Particle Counting, ASTM D7777 / D4052 Density and ASTM D2624 Conductivity.

The particle counter has been built to use the standard military portable batter shown above or can be run from the battery pack found in the PEAK kit, or from wall power. Pictured below the Particle Counter can be ordered to come with the backpack version which is used for example on an aircraft carrier flight deck. The Particle counter has passed testing from -30°C to 50°C and proven it is submersible meaning it can handle operation in any conditions of weather.

Particle Counter Brochure (Density and Conductivity)

Features:

- The most mobile particle counter in existence, with a backpack carrying option.

- The rugged design can withstand extreme weather conditions and still operate effectively.

- ASTM D7619 Equivalent Accuracy to determine fuel quality.

- Military Hardened Design tested for field use.

- Calibrated to ISO 11171 Standards.

- Compliant with ATPD-2424A.

- High Resolution Color Display.

- With Built in Conductivity ASTM D2624 and Density ASTM D7777 / D4502

The Particle Counter Battery (pictured above) is a high-capacity 99Wh, 6.8 Ah Lithium-ion battery. When fully charged, it enables the particle counter to operate continuously for up to 8 hours. With this capacity, it supports a minimum of 200 tests before requiring recharging. Meets IATA guidelines for Air Transport.

Technical Specifications |

|

Operation |

|

Principle of operation | Laser obscuration |

Test methods | ASTM 7619 |

Particle size range | 4µm(c) to 30µm(c) |

Calibration | In accordance with ISO 11171 |

Test duration | 2.5 Minutes |

Pressure (max) | 400 PSI |

Sample temperature range | -30 to 50 °C |

Operating temperature range | -30 to 50 °C |

Sampling method | Bottle sample or online connection |

Display and control system | 160 color dimmable display, red/green ISO grading, dual backlit push buttons |

Measurement |

|

Measuring channels | 4 size channels displayed on instrument 4µm, 6µm, 14µm, 30µm |

Coincidence error limit | 60,000 particles/ml ≥4µm(c) with ≤ 5% co-incidence error (ISO 11171) |

Sample viscosity (max) | 64 mm²/s (cSt) |

Sample volume | 80 ml |

Sample delivery | Integral Piston Pump downstream of the cell |

Sample flow rate | 30 ml/min test, 60 ml/min flush |

Data Management |

|

Results format | Cumulative, Particles/ml, ISO 4406 cleanliness codes/classes |

Memory | 200 Test points |

External Data Output | memory output to PC or Printer |

Power requirements |

|

Voltage | 12 – 36 Vdc |

Battery | 99Wh, 6.8 Ah Lithium ion (8 hours, 200 tests min.) |

Physical |

|

Size (HxWxD) / Weight (w/ Battery) | 7″ X 7″ X 11.8″, 11.5 lbs. |

Construction | Aluminum Case |

Environmental | IP67, MIL-STD-810 Method 512-Immersion Procedure 1 (1 meter, 5% salt, 30 minutes) |

Carry case | Padded 800d face Ultra-PE blended with high-tenacity polyester shoulder carry case |

Hose connecters | 1620 Minimess |