The ULP-CTD Ultra Low Power CTD Line

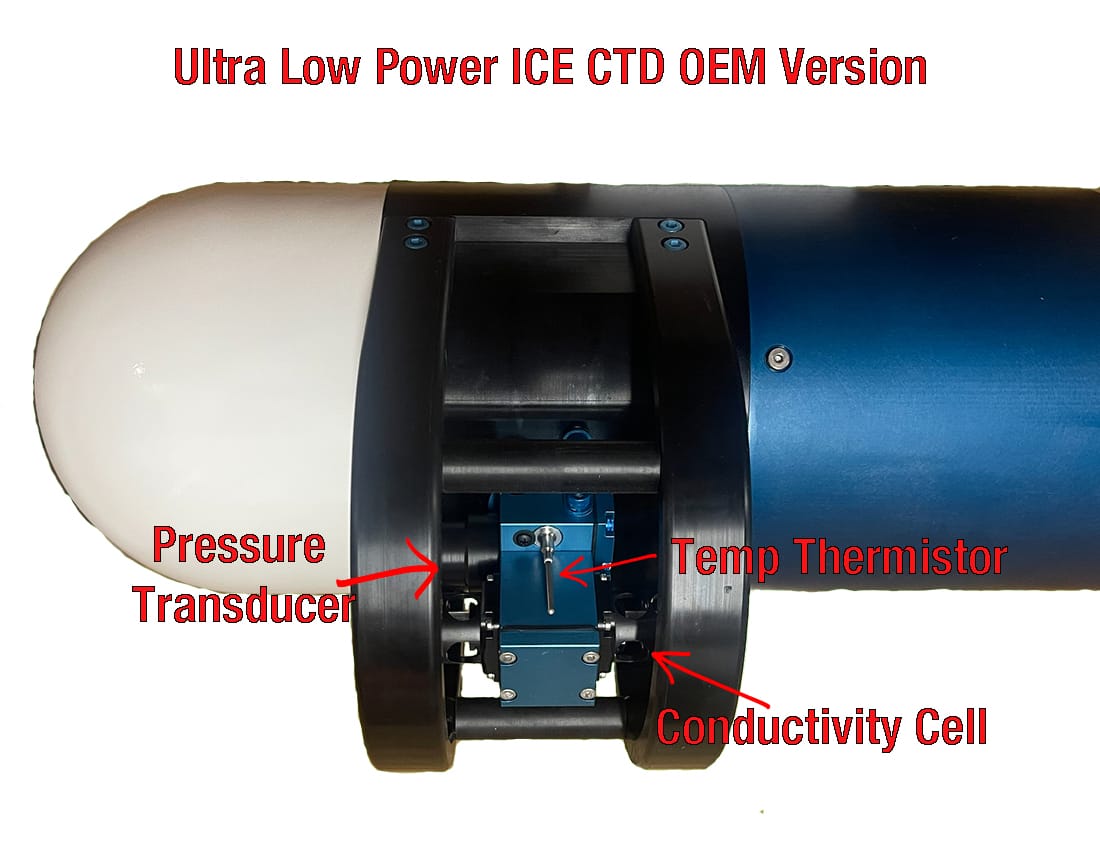

The D-2 Inc. ULP-CTD is our popular Closed Field Hybrid CTD, built to use a much lower amount of power, only 4 mA, to offer the market with one of the lowest power CTD’s that also offers closed field measurement precision and flow through no pump designs.

This is the ULP-CTD an extremely low power Conductivity, Temperature and Depth Sensor built for full Ocean depth precision and use. This is a brand new patented US Technology and the first brand new way to measure conductivity in 30 years. This new conductivity sensor technology allows for smaller lightweight design, improved precision and free flushing of the sensor (no pump required). Full Ocean depth precision of .0003 S/M while only using 4 mA of power.

This new ULP-CTD has the latest in solid state electronics & processing, direct serial data, USB, RS-232.

The D-2 Inc. CTD now has a paper published with sea trial data from WHOI and the BATS sampling program: Continued Development and Evaluation of the D-2 Inc. Hybrid CTD Sensor

EXCLUSIVE FEATURES:

The new ULP-CTD technology offers some new features previously unavailable in the market of deep ocean conductivity sensors.

- The CTD can provide full ocean depth precision, it has the accuracy and resolution to measure conductivity all the way to the bottom of the ocean.

- New Hybrid 100% Internal Field Free Flushing Conductivity Sensor.

- High Speed Sheathed Thermistor ~ TC = 60 mS (2 mm diameter) with integral Temperature Reference Standard

- Industry Standard Silicon Pressure Sensor Full Thermally Compensated

- Extreme Low Power Use of 4 mA.

- Real Time Clock with Programmable Interval Sampling as required & 128 Mbit data storage.

- Compatible with commercial wire-line telemetry packages available from third parties.

- Each Sensor Calibrated over the range of 2.6 to 6 S/cm in a computer controlled bath, using natural seawater; water sample at each point is compared to IAPSO seawater

- 3400 m Aluminum, 7000 m 17-4PH SS, or 10500 m titanium housing.

See the Full Product Brochure: 310-001RULP3 Ultra Low Power CTD Brochure

Data Sheet: CTD & ULP Data Sheet

Product Specifications

Product Specifications:

Conductivity:

Range: 0-7 S/M, Resolution: 0.00004, Initial Accuracy: +/- 0.0003 S/M, Typical Stability: +/- 0.0003

Response < 0.065 msec Free Flushed @ 100 cm/min Velocity Through Water

Temperature:

Range: -5C to 35C, Resolution: 0.0002, Initial Accuracy: +/- 0.001, Typical Stability: +/- 0.0002C per Month. Response 0.100 Sec

Pressure:

Range: User Set, Resolution: 0.001% F.S., +/- 0.015% F.S., +/- 0.02% F.S. Year.

Response < 0.015 Sec

Power Consumption:

4 mA (all sampling speed) ULP Version

Sampling Speed:

Sampling Speed: 1 or 2 Hz, 1 or 2 Frames of CTD data / Second

Auxiliary Sensors: The unit has an 8 Channel 12 BIT A/D Range 0 – 3.3VDC A/D convertor available for Auxiliary Sensors

Consult Factory for Auxiliary Channel Input Filter Conditioning & Response

Auxiliary Sea Cable Telemetry Module:

Sea Cable:

Inner conductor resistance 0 to 350 ohms

Modem Baud Rate: Data UP Rate 9600 BPS

Bi Directional Serial Command Channel 300 BPS Full Duplex

Power For External Sensors : 1 Amp at 15VDC

The ULP-CTD Sensor

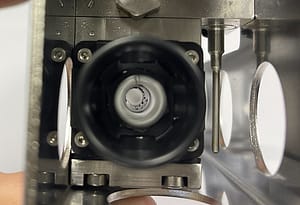

The Unique Closed Field D-2 Conductivity Cell:

The D2 CTD utilizes a new Hybrid Conductivity Sensor. The Hybrid sensor is a completely new concept in a high precision conductivity sensor. It combines the performance advantage of the traditional 3 electrode sensor where the end electrodes are electrically tied together ensuring there is no external electric field. That electrode system couple with a novel inductive drive, eliminates the need for additional center electrode, or other electrodes in the measurement field. The two-electrode sensor with inductive drive is hence called a Hybrid as it incorporates the best aspects of both the electrode type & inductive type conductivity sensors that have a strong history of performance oceanographic conductivity measurements.

Closed Field but Flow Through Design, Best of Both Worlds…

As the two outside electrodes are sorted together electrically so by theory the outside potential of the sensor is “zero” hence there is no current flow outside the path sorted by the end electrodes. The inductive drive creates a current that flows through the center measurement region, the current flows in direct proportion the conductivity of sea water. This current is collected by the end electrodes and passed through a simple current to voltage transformer. As current is in direct proportion to the conductivity of sea water and the magnitude to the drive signal. The drive signal level can be precisely controlled, and the collection electrodes and shorting path can be constructed to have very low impendence as compared to the external sea water path, hence the ‘all’ of the current flows through the short, and, hence the current measurement transformer.

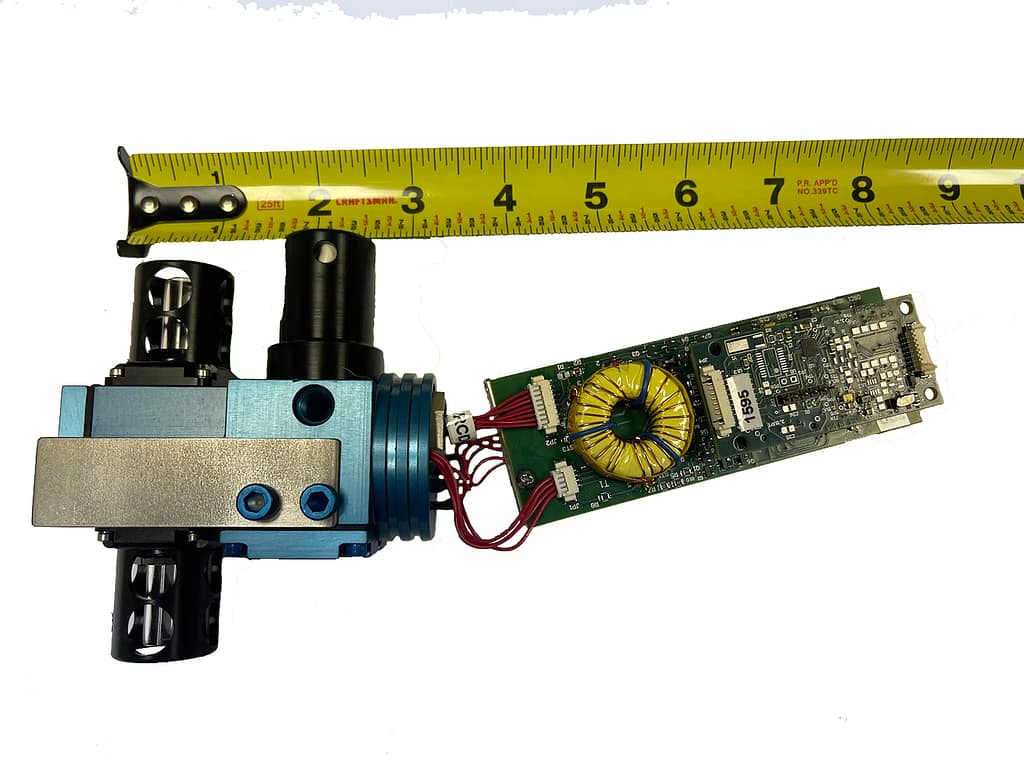

The result is a two-electrode cell that is ½ the length of a traditional a 3-electode cell and has a large center diameter. A sensor that can free pass water through the cell without the need for a pump in almost all applications. In applications where a pump is needed, say for biological control, this can be easily added as the sensor measurement volume is 100% enclosed in the sensor and the addition of tubing a pump will not affect the calibration. The sensor is fully described in US Patent #9,410,910.

D-2 Hybrid Conductivity Sensor

The Heart of the D-2 Incorporated CTD is its novel new ‘patented’ Hybrid conductivity sensor. This sensor has all the advantages of a 100% internal field cell, while support a length that is ½ that of other competing sensors. In addition, the center sensor diameter is nearly twice as large without cavities allowing the sensor to be free flushed in most applications. However, as the sensor measurement is 100% internal, a pump can also be used for those customer’s requiring even higher response, or limiting biological fouling during non-measurement periods.

D-2 Temperature Sensor

D2 inc. utilizes sophisticated A/D acquisition electronics, ultra-stable thermistor, and state-of-the-art calibration provide the standards-level performance of an expensive AC bridge and platinum thermometer at a small fraction of the cost. The D2 CTD is unaffected by shock and vibration, temperature highly accurate and uses the same aged and thermal shock qualified thermistor as other leading instrument suppliers. The thermistor is combined with an ultra-stable resistance reference which are both mounted within the thermistor deployment sheath to ensure temperature homogeneity, this aspect is vitally important for deep ocean measures where extreme temperature precision is an absolute requirement.

Temperature Sensor High Speed Response:

The temperature sensor is available in 2 versions, a 2 mm outside diameter industry standard size, and a high speed 1 mm outside diameter best in the business response for the most demanding applications.

Real-time CTD data is transmitted via the RS-232 serial interface in ASCII characters. The D2 CTD must be externally powered, data can be logged in internal SRAM memory or it can be telemetered up a wire line using commercially available wireline telemetry systems.

D-2 Depth Sensor

The D2 CTD uses a high-accuracy, high-resolution pressure sensor. The D2 CTD’s strain-gauge pressure sensor is offered in a wide range of full-scale values up to 1000 Bars. Pressure outputs are fully compensated for the effects temperature and is performed internally using state of the art numerical techniques.

Low Power CTD Makes Arctic Research possible:

The Lower Power CTD’s used in Arctic Ice Program “ITP” Ice Tethered Profilers now called the “TOP” Tethered Ocean Profilers, see images below… Visit the WHOI program page and track our sensors live: https://www2.whoi.edu/site/itp/

Custom OEM Designs of the Ultra Low Power CTD

D-2 Inc. CTD News...

Ocean News 9: Titanic Being Eaten By Rust? Shocking NASA Data

Ocean News 9: The Titanic Being Eaten By Rust? Shocking New Sea Level Rise Data from NASA & More.. In this episode of Ocean News

D2 Hybrid Ocean CTD Dives into Oceanographic World Interview

D2 Jumps Headlong into Oceanography with its Hybrid CTD Innovation is rampant in the subsea sector, and D2 Hybrid Ocean CTD is a perfect example,

Ocean Business 2025 News Special: Science Tech Ocean News 8

Ocean News 8: Ocean Business 2025 Special: Innovative New Oceanographic and Marine Science Tech IRL This is a special episode of Ocean News from Southampton

D-2 Incorporated Exhibiting at Ocean Business 2025

Southampton United Kingdom, the home of the National Oceanography Centre (NOC) and the biannual Ocean Business hands on technology exhibition and training forum. D-2 Incorporated

Ocean News 7: AMOC Slowing Down? HydroPhones Sub Hunting

Ocean News 7: Is AMOC Slowing Down? HydroPhones for Submarine Hunting, DEEP Underwater Habitats https://youtu.be/KMswf4PWBUo 🌊 Dive into the latest Ocean News with Episode 7

Fast CTD Delivery Times and Quick Calibration Turnarounds

Oceanography has a CTD Lead Time Problem The Oceanographic Community studies the Earth’s Oceans providing critical information about our planet. They require Fast CTD Delivery